Understanding mesh size is essential for anyone working with powdered materials, whether in construction, ceramics, coatings, filtration, or industrial manufacturing. Glass powder, like many mineral products, is classified by mesh size. But what does “mesh size” actually mean, and why does it matter for performance?

This guide provides a comprehensive overview of everything you need to know, from basic definitions to practical applications of mesh size in glass powder.

What Does “Mesh Size” Mean?

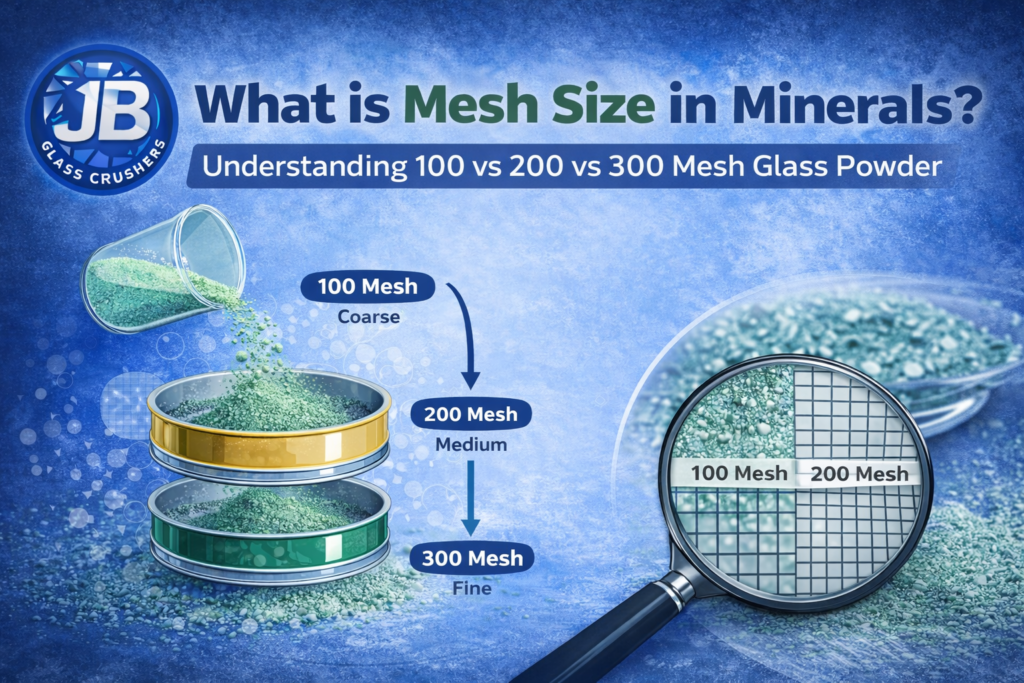

Mesh size refers to the number of openings (or holes) per linear inch in a sieve screen. It is a measure that tells you how fine or coarse a powder is.

- Higher mesh number = smaller particles

- Lower mesh number = larger particles

For example:

- 100 mesh: particles small enough to pass through a screen with 100 openings per inch

- 200 mesh: finer particles that pass through 200 openings per inch

- 300 mesh: ultra-fine particles that pass through even smaller openings

Mesh size is a traditional way of indicating particle size distribution before digital particle analysis became commonplace.

Mesh Size vs. Micron Size

Although mesh size is a useful industry standard, many labs and buyers prefer micron measurements because they are more precise.

Here’s a rough conversion reference:

| Mesh Size | Approx. Micron Size | Particle Description |

|---|---|---|

| 100 mesh | ~150 µm | Coarse powder |

| 200 mesh | ~75 µm | Very fine powder |

| 300 mesh | ~45 µm | Ultra-fine powder |

This table helps you quickly understand how mesh correlates with actual particle diameter.

Why Mesh Size Matters

Mesh size affects several important material properties:

1. Reactivity

Smaller particles (higher mesh) have greater surface area, which increases chemical reactivity when used as a supplementary cementitious material.

2. Strength Development

In concrete and mortar systems, finer powders can enhance long-term strength due to better particle packing and pozzolanic activity.

3. Flow & Workability

Finer powders can affect water demand and workability, which may require mix design adjustments.

4. Finish & Surface Quality

In coatings, tiles, and ceramics, finer mesh sizes produce smoother surfaces and improved finishes.

5. Cost

Finer mesh sizes require more grinding energy and may cost more per kilogram than coarser grades.

Common Mesh Sizes & Their Uses

100 Mesh (Coarse)

- Particle size ~150 µm

- Used mainly as a filler or fine aggregate replacement

- Ideal when high reactivity isn’t required

- Useful in textured finishes, decorative surfaces, and concrete blocks

200 Mesh (Medium)

- Particle size ~75 µm

- Balanced reactivity and cost

- Suitable for cement replacement (10–20%)

- Used in tiles, ceramics, coatings, and general industrial applications

300 Mesh (Fine)

- Particle size ~45 µm

- Highly reactive due to large surface area

- Often used where strength and durability are critical

- Ideal for high-performance concrete and precision products

Mesh Size in Glass Powder

For glass powder specifically, mesh size determines:

- How active the powder will be in concrete

- How smooth the finish will be in tiles or coatings

- How well it will fill voids and densify structures

A glass powder ground to 200–300 mesh is commonly used for:

- Cement replacement in concrete

- Fluxing agent in ceramic bodies

- Fine filler in coatings and polymers

Coarser glass powder (~100 mesh) is often used:

- As a sand replacement

- In decorative aggregates

- In applications where cost efficiency is more important than chemical reactivity

How Mesh Size Affects Performance

Because mesh size indirectly controls surface area, it significantly influences:

Concrete

Finer mesh improves:

- Long-term compressive strength

- Durability and resistance to chlorides

- Microstructure refinement

Coarser mesh:

- Improves economy

- Enhances granular packing

Ceramics & Tiles

Finer mesh contributes to:

- Better vitrification

- Lower firing temperatures

- Improved surface smoothness

Coatings & Polymers

Finer powders:

- Improve texture

- Increase abrasion resistance

- Enhance visual finish

Coarser powders:

- Lower cost

- Add bulk and mechanical strength

Choosing the Right Mesh Size

To select the best mesh size for your application, consider:

- Required performance – strength, finish, durability

- Mix design – impact on workability and water demand

- Cost targets – finer mesh costs more to produce

- Application type – structural vs decorative

For most industrial uses, 200 mesh offers a balanced mix of performance and cost.

Mesh Size Testing & Quality Control

Reliable suppliers provide:

- Particle size distribution reports

- Sieve analysis certificates

- Micron and mesh correlation charts

- Bulk density and moisture information

Always verify quality before bulk orders, especially for precision applications.

Why Mesh Size Matters for Sustainability

Choosing the right mesh size can also reduce:

- Cement consumption in concrete

- Energy use in processing

- Waste in trimming and finishing

Optimised particle size distribution enhances material efficiency and can support sustainability goals in green building standards.

Conclusion

Understanding mesh size is fundamental when working with powdered materials like glass powder. Mesh size determines:

- Particle diameter

- Reactivity

- Strength and durability performance

- Cost and processing requirements

Whether you are a contractor, manufacturer, or industrial buyer, knowing how mesh size affects your material will help you choose the right grade for your application — and get the best value from your investment.