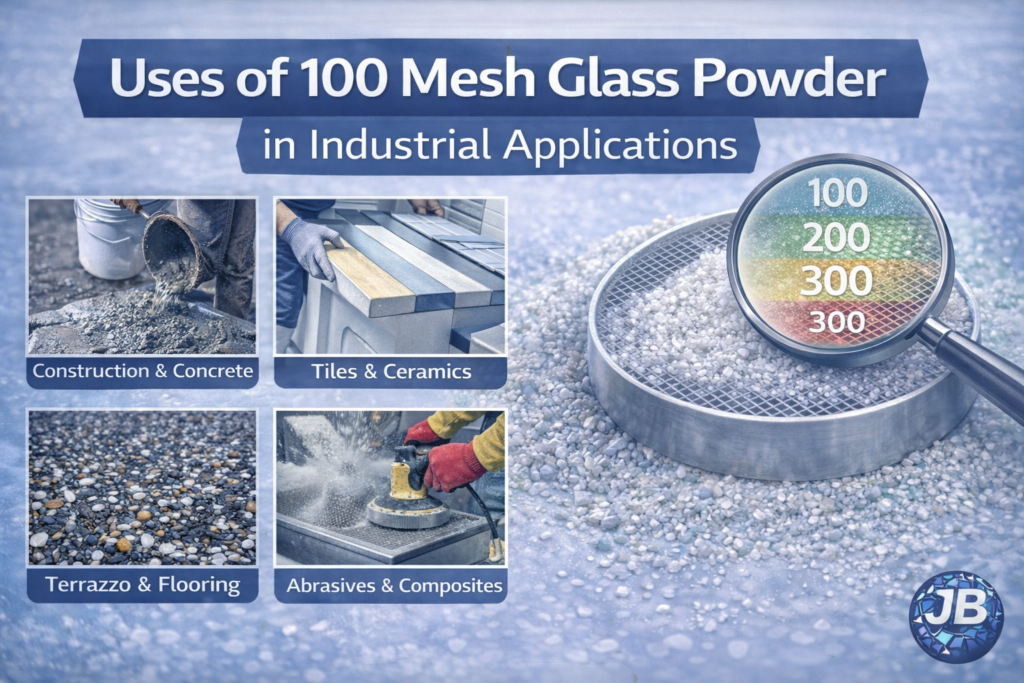

100 mesh glass powder (approximately 150 microns) is one of the most versatile and cost-effective grades used across multiple industries. Due to its relatively coarser particle size compared to 200 or 300 mesh grades, it functions more as a fine aggregate or functional filler rather than a highly reactive pozzolanic material.

Its balanced particle size makes it ideal for applications where texture, bulk filling, cost efficiency, and structural reinforcement are more important than ultra-fine chemical reactivity.

What Is 100 Mesh Glass Powder?

100 mesh glass powder means the material passes through a sieve with 100 openings per linear inch. The average particle size is approximately 150 microns, giving it a fine sand-like consistency.

Key characteristics:

- Moderate surface area

- Lower grinding cost

- Good mechanical strength contribution

- Stable chemical composition

- Economical bulk pricing

Major Industrial Uses of 100 Mesh Glass Powder

1. Construction & Concrete Industry

Sand Replacement in Concrete

100 mesh glass powder can partially replace natural sand in:

- Non-structural concrete

- Masonry blocks

- Paver blocks

- Kerb stones

- Precast products

Benefits:

- Reduces dependency on river sand

- Improves particle packing

- Cost-effective aggregate alternative

- Supports sustainable construction practices

Cementitious Fillers

Though less reactive than 200 or 300 mesh grades, 100 mesh powder improves density and reduces voids when used in moderate percentages.

2. Tiles & Ceramic Manufacturing

In ceramics, 100 mesh glass powder acts as:

- A fluxing additive

- A filler material

- A vitrification enhancer

Benefits:

- Improves surface smoothness

- Reduces firing defects

- Lowers production cost

- Enhances glaze bonding

Because of its larger particle size, it contributes structural bulk while still assisting in melting during firing.

3. Decorative & Architectural Applications

Terrazzo Flooring

100 mesh glass powder provides:

- Textured finish

- Visual sparkle

- Enhanced durability

- Recycled aesthetic appeal

- Epoxy & Resin Flooring

Used as a decorative filler to:

- Add strength

- Improve wear resistance

- Create patterned surfaces

4. Abrasives & Surface Treatment

Due to its angular particle shape, 100 mesh glass powder is suitable for:

- Light abrasive blasting

- Surface cleaning

- Rust removal

- Polishing compounds

Its hardness makes it an effective yet environmentally safer alternative to silica sand.

5. Road & Infrastructure Applications

Glassphalt (Glass in Asphalt)

100 mesh glass powder can be incorporated into asphalt mixes to:

- Improve skid resistance

- Enhance surface durability

- Utilise recycled materials

- Reduce landfill waste

6. Filtration & Media Support

While finer grades are used in precision filtration, 100 mesh can be applied in:

- Support layers in filter beds

- Drainage systems

- Industrial filtration backfill

Its chemical stability ensures non-reactivity in water systems.

7. Polymer & Composite Fillers

In plastics and composite materials, 100 mesh glass powder:

- Improves dimensional stability

- Enhances hardness

- Reduces shrinkage

- Acts as cost-efficient filler

Used in:

- Molded parts

- Industrial housings

- Composite boards

Performance Advantages of 100 Mesh Glass Powder

Cost Efficiency

Lower grinding energy makes it more affordable than ultra-fine grades.

Sustainable Material

Made from recycled glass, reducing landfill waste.

Mechanical Strength Support

Enhances compressive strength when used properly.

Reduced Sand Mining

Supports eco-friendly infrastructure development.

When to Choose 100 Mesh Over Finer Grades

Choose 100 mesh if:

- You need a bulk filler

- Cost control is important

- High reactivity is not required

- Application is structural or decorative

- Sand replacement is the primary goal

If pozzolanic reactivity is required (cement replacement), 200 or 300 mesh may be more suitable.

Industrial Demand in India

With increasing restrictions on river sand mining and growing emphasis on recycled materials, 100 mesh glass powder is gaining popularity in:

- Precast manufacturing

- Affordable housing projects

- Infrastructure development

- Sustainable construction initiatives

Bulk industrial buyers prefer this grade due to:

- Lower price per kg

- Easy availability

- Wide usability across sectors

Conclusion

100 mesh glass powder is a versatile industrial material offering cost efficiency, sustainability, and strong mechanical performance. While it may not provide the high chemical reactivity of finer grades, its ability to function as a durable filler and sand alternative makes it highly valuable in construction, ceramics, abrasives, and composite manufacturing.

For industries seeking a balance between performance and affordability, 100 mesh glass powder is an excellent solution.