Use of Glass Powder in Industrial Settings

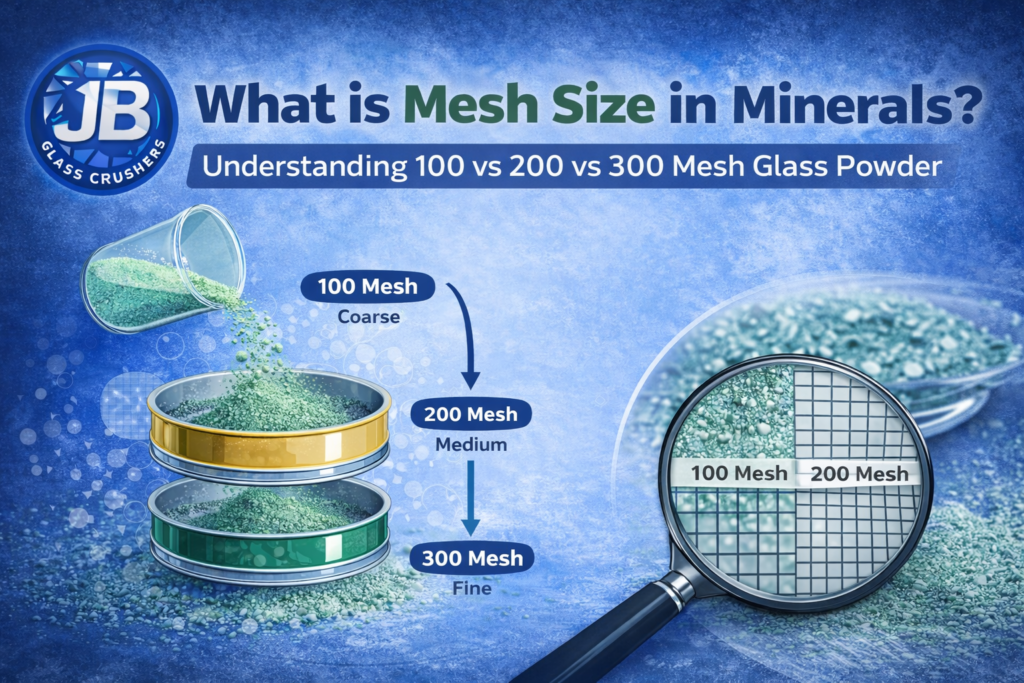

High-Performance Industrial Applications by JB Glass Crushers – Glass powder, finely milled and processed from recycled glass cullet is a highly versatile industrial material. At JB Glass Crushers, we manufacture premium quality glass powder in mesh sizes ranging from 100 mesh to 300 mesh, delivering performance benefits across multiple industrial sectors. Whether you are developing […]

Use of Glass Powder in Industrial Settings Read More »